MICRO-SURFACING PAVEMENT

Equipment checked and approved by INMETRO, designed and built according to the technical manufacturing and safety standards required for certification.

MICRO-SURFACING PAVEMENT – TRUCK

Sturdy Equipment = quality asphalt

Specially developed for Truck or Bi-Truck chassis assembly.

This model well applies to urban projects, but also with great road performance.

These machines have as their main feature the biggest storage capacity of the market.

Main features:

EMULSION/WATER TANK: Rectangular shape, bipartite with manhole cover, double safety valve, level canoe for protection and containment of the stored products, bottom valve and valve trigger, level clock for water emulsion, access ladder to the top.

ADDITIVE TANK: Pressurized tank made of polished stainless steel, safety valve, manometer, drain, level viewer, regulator for internal pressure control, flow reading by rotameter, flow control on the control panel.

AGGREGATE SILO:in conical shape with lateral reinforcements, equipped with deflector and vibrator, floodgate with graduated regulation.

CONVEYOR BELT: Built in profiles and structural tubes, armored rollers, rubber coated traction roller, driven by an hydraulic motor coupled to a planetary reducer sitting on a cushion.

FILLER DEPOSIT: Flanged bipartite body, upper body fixed to the aggregate silo, closing lid and grid to prevent the passage of clods, serrated grid to help the bag opening, dosage control through the rotation of the feeding shaft with control panel drive.

MIXER:type PUG MILL (designed to use gravel up to ½”) of double shaft with interchangeable arms and blades, shaft rotation regulation by flow controller, bipartite mixer box with removable bottom, rotation regulation of the synchronized hydraulic motors.

FINISHING TABLE: Adjustable application opening by hydraulic pistons, minimum is 114,1 inches and maximum is 165,3 inches. Higher and more robust finishing table box, telescopic helicoids that move the asphalt mixture with a larger diameter, driven by hydraulic motors, telescopic platforms and handrails that accompany the opening and closing of the table, protection plate against splashes, manual control of the thickness of the applied mixture, finishing ruler with height and slope adjustment, supported on skis.

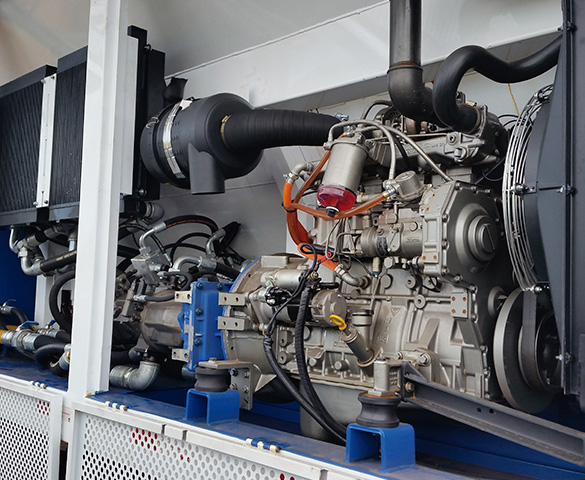

HYDRAULIC SYSTEM: Composed of a set of pumps with two powerful radiators for cooling the system, driven by a NEW 4-cylinder in-line turbo diesel engine, mounted on cushions, complete electrical panel, water cooling system (radiator and fan), exclusive diesel tank for powering the plant engine.

ELECTRICAL CONTROL AND READING PANEL: Emulsion and water pumps, conveyor, filler, mixer.

HYDRAULIC CONTROL PANEL: Lifting and adjustment of the mixer inclination angle, drive and rotation direction of the shafts, direction of the mixer discharge spout, right and left lifting tower, displacement of the cross bar, right and left finishing opening, drive of the direct and left shafts of the finishing table helicoids.

CLEANING SYSTEM:High pressure washer for cleaning the equipment and pressurized diesel tank for cleaning the entire emulsion system.

SR 7000 MP

Truck

60-120 t/h

1,8 gal

1102,3 pounds

634 gal

554,7 gal

79,2 gal

MOTOR MWM 4 CIL. TRUBO DIESEL 104 HP

FLUID-POWER

Emulsion 12,1 gal/h

water 9,2 gal/h

Plug-mil (Double Axis)

Motovibrator (IP66) 0,15cv

114,1 inches to 165,3 inches

SR 9000 MP

Bi-Truck

60-120 t/h

2,3

1102,3 pounds

634 gal

554,7 gal

79,2 gal

MOTOR MWM 4 CIL. TRUBO DIESEL 104 HP

FLUID-POWER

Emulsion 12,1 gal/h

water 9,2 gal/h

Plug-mil (Double Axis)

Motovibrator (IP66) 0,15cv

114,1 inches to 165,3 inches